- Home

- /

- Green mission

Green mission

We care about the future of our planet.

Sustainability, ecology and productivity: these are the three concepts that sum up our commitment to a more environmentally friendly future.

More and more scientific evidence shows that our lifestyles and production processes which have established themselves throughout history are unsustainable, non-ecological and threaten not only the environment in which we live and our lives, but also the longevity of companies, which more than ever must deal with the issue of eco-sustainability.

Eurostampi, which is strongly oriented towards recycling and has always been in line with the highest international standards in terms of environmental compliance, implements concrete processes and sustainable behaviour on a daily basis in order to optimise energy consumption and minimise waste production.

Our commitment for a sustainable future

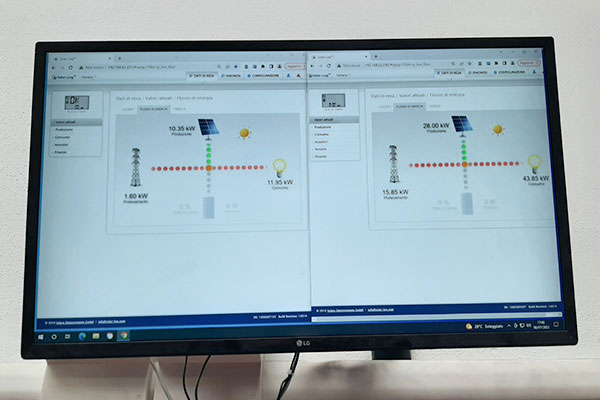

Photovoltaic systems

We have chosen photovoltaic systems to produce electricity in our plants: we take advantage of the sun’s clean and inexhaustible energy to meet 50% of our company’s energy needs, thus avoiding CO2 polluting emissions.

Recycling and regeneration

Each waste product resulting from the processing cycles is recycled and regenerated. Our R&D department is constantly looking for materials to develop products with the least possible environmental impact and that guarantee both recycling and complete regeneration.

Simple daily gestures

All the machines we’ve designed and manufactured for the Ecology are also used in the company, such as the Ecopress for compacting nylon and cardboard or the Rotary located in the refreshment area, actively used by the Eurostampi team to crush plastic bottles, cans and coffee glasses.

Our hydrothermal system

As a result of the expansion of our company plant, we installed a hydrothermal system for heating and cooling the various plant areas, which allows for:

- the recovery of hot water produced by the presses when moulding plastic materials

- the air conditioning of the entire production and management area

- the cooling of oil pumps and machine tools, improving the technical and functional parameters of both the machines and the production process