- Home

- /

- Moulds manufacturing

- /

- Die casting moulds

Die Casting Moulds

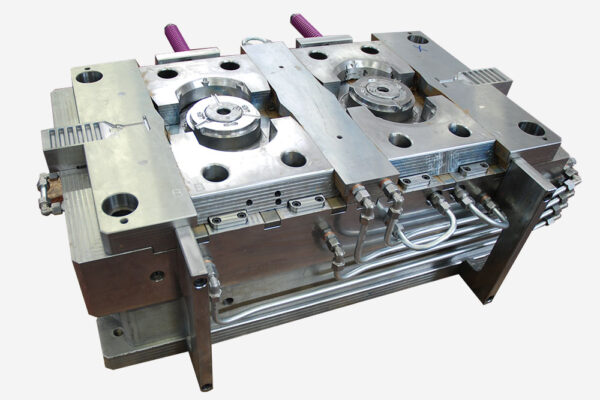

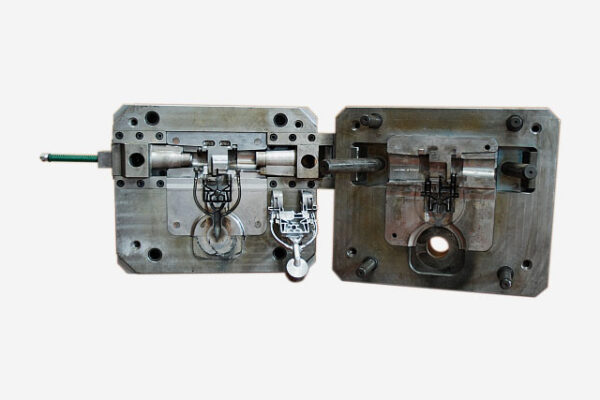

Design and manufacturing of die casting moulds

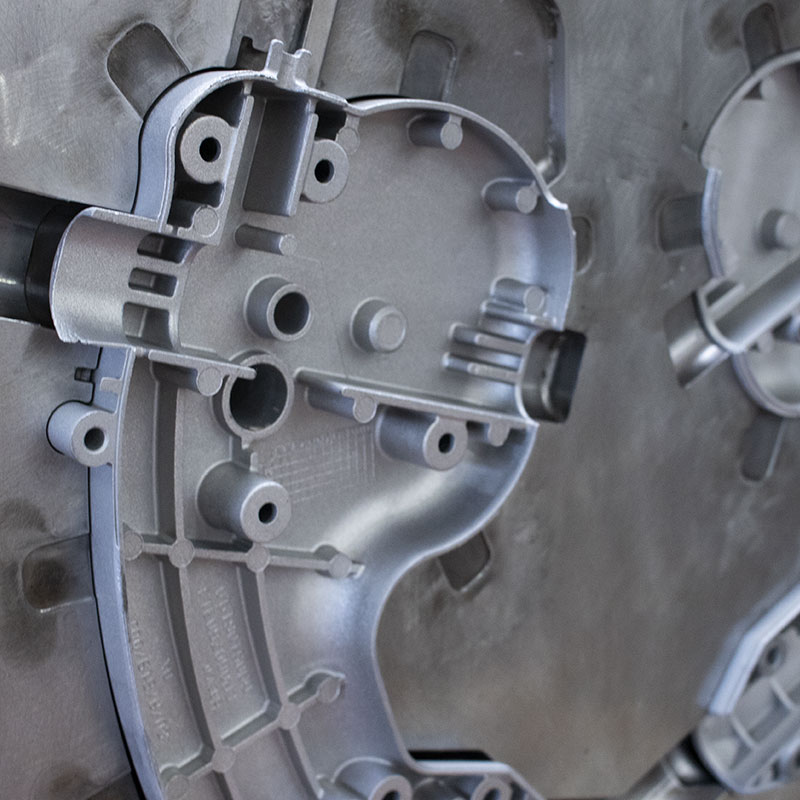

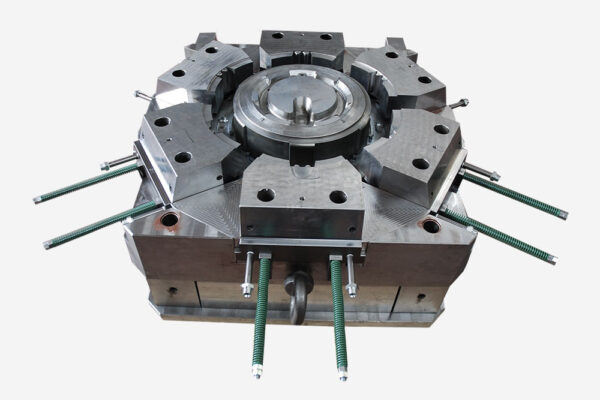

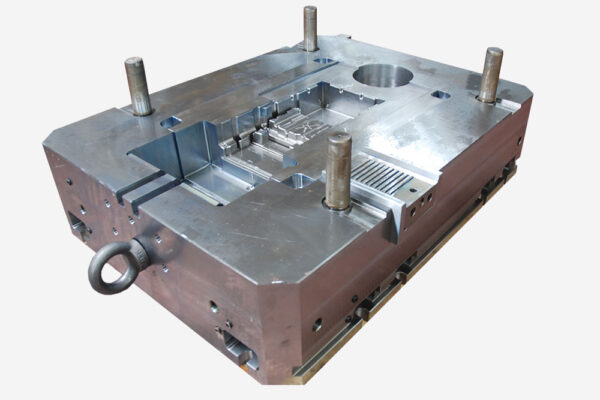

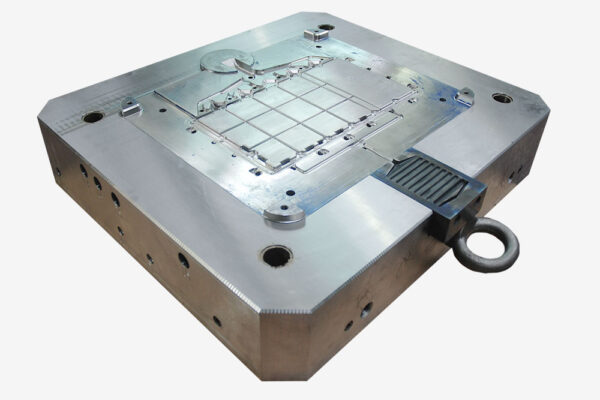

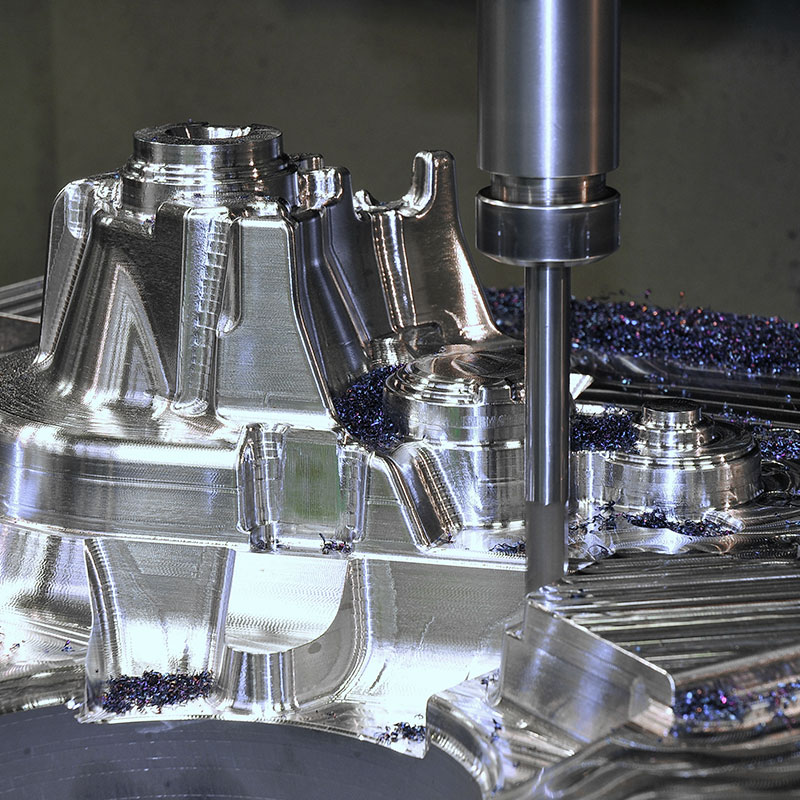

Thanks to the long experience in mould construction, the team’s extensive technical know-how and a state-of-the-art machine fleet, Eurostampi designs and manufactures high precision metal alloy die casting moulds, responding with professionalism and competence to any customer need.

Our qualified staff is ready to assist customers from the preliminary stages of the project, offering a complete service that begins in our technical office with feasibility studies, industrialization of the details, 2D and 3D design and continues in the workshop, with the construction of die-casting moulds and constant checking of the progress of the project, thanks to industry 4.0 monitoring.

Die casting moulds for aluminium, magnesium and zamak

Since 1988 Eurostampi has been designing and manufacturing die casting moulds for aluminium, zamak, magnesium and thermosetting up to a maximum of 2,000 kg.

We produce aluminium shearing moulds for automatic moulding lines and for large series to eliminate from ingate issues, air vents and any deformation caused by the moulding.

We also make control jigs for pieces or for mechanical processing, and produce aluminum equipment to position the casting on measuring control machines.