- Home

- /

- Services

Our services

You think of it, we'll develop it

Eurostampi has always pursued objectives of the utmost quality and continuous improvement of its products.

This is why, in addition to the production of plastic injection moulds and die casting of aluminium, magnesium and zamak, we offer a complete range of customised services: product design, prototyping, engineering, mould design, production, testing and after-sales service are our winning features.

With over 30 years of experience in the sector, we are the reference point for customers who are looking for a partner and single point of contact, competent and reliable, capable of taking care of the entire project, from the initial concept to the delivery of the finished product in plastic or aluminium, pre-assembled or single, painted or tumbled, with the subsequent mechanical processes and finishes requested by the customer and by the field of application of the particular item.

Feasibility study and preliminary cost assessment

The customer’s project is initially subjected to a feasibility analysis by our Technical Department.

Once the feasibility of the project has been ascertained, a preliminary phase of analysis regarding the production and processing costs of the project follows, during which the fundamental features of the moulds and therefore of the final products are identified, which will then be further developed in the next phase of design or eventual co-design.

The latter consists in the search for possible technical solutions in creating the final mould object or in the three-dimensional scanning of already existing parts in the absence of a 3D drawing.

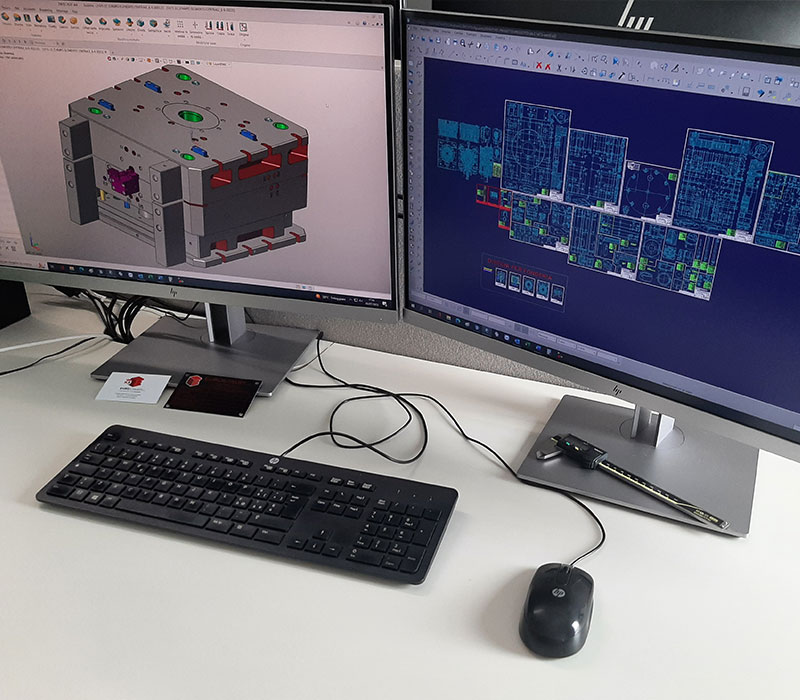

CAD/CAM design

We are equipped with 4 stations with the best CAD software for the analysis, design and execution of three-dimensional drawings of parts, so as to follow the customer in the co-design and industrialization phase of the particular item. During this phase we work with tight tolerances, in order to acquire excellent quality surfaces so as to obtain the best possible processing in the subsequent phases.

We have 2 CAM stations for programming and executing the toolpaths of CNC machines, thanks to which we transform projects into physical parts.

The continuous updating of the latest versions of CAM and CAD allow us to work to the best of our abilities.

CAD Programmes:

- ThinkDesign

- ZWD

CAM Programmes:

- Tebis

Rapid prototyping

During this phase we carry out samples by rapid prototyping (RP) for final objects in plastic, rubber and aluminium.

Moreover, we can make aluminium parts from the 3D model by processing block machine tools. Customers choose us because we are able to guarantee accessory machining on particular items with very low tolerances, for which we use wire EDM so as to meet the strict specifications required.

We carry out externally and at the request of the customer resistance assessments, trials and assembly tests of the prototypes made: in this way, we obtain the definite cost of the final piece, cost optimization and we can proceed with the preparation of the final design of the necessary equipment.

Mould production

Eurostampi designs and manufactures injection moulds for plastic material and die casting moulds for aluminium, zamak and thermosetting, up to a maximum of 120,000 Kg.

In the automatic moulding lines and large series, aluminium blanking moulds are built to to eliminate from ingate issues, air vents and any deformations caused by moulding.

Eurostampi is also involved in the design and construction of control jigs for pieces or for mechanical processing.

We build aluminium equipment to position the jet on (DEA) measurement control machines.

3D Functional Checks

Once the mould has been made, thanks to the help of sophisticatedthree-dimensional control tools, the Eurostampi team carries out accurate tests and functional checks on each component of the mouldinternally, to verify the quality and ensure consistency with customer requests.

In particular, sealing and dimensional checks are carried out, paying particular attention to the coupling between the various components.

Testing and quality control

After passing all tests carried out by our quality control department, the final test takes place. This enables us to be certain to deliver to customers a perfect die-casting or injection mould in all its components, ready to be placed in the production cycle.

Assembling and shipping

Once tested and verified, the various mould components are assembled, to check closures, flow, seals and all the couplings to ensure perfect functioning at initial mould use.

With the aim of offering a complete and professional service to customers, Eurostampi is equipped with a precise and punctual mould transport system, capable of guaranteeing timely delivery and the certainty that the quality of the mould does not alter during shipping.

Supply of moulded object

Eurostampi provides you with the moulded piece: whether it is plastic or aluminium, with mechanical machining or subsequent finishing, painted or tumbled, pre-assembled or single.

Eurostampi is also certified for the injection moulding of materials and plastics, the production of metal parts according to the customer’s drawings and the control of the metal die casting process.